Since first launched in 1999, CAC has experienced over 20 years’ development, become world largest agrochemical exhibition and an UFI approved International event since 2012. Driven by the innovated dual platforms of online and offline, CAC2023 will create world exchange and cooperation platform linking upstream and downstream and connecting the whole industrial chain of planting inputs at home and abroad.

.png)

23rd China International Agrochemical&Crop Protection Exhibition

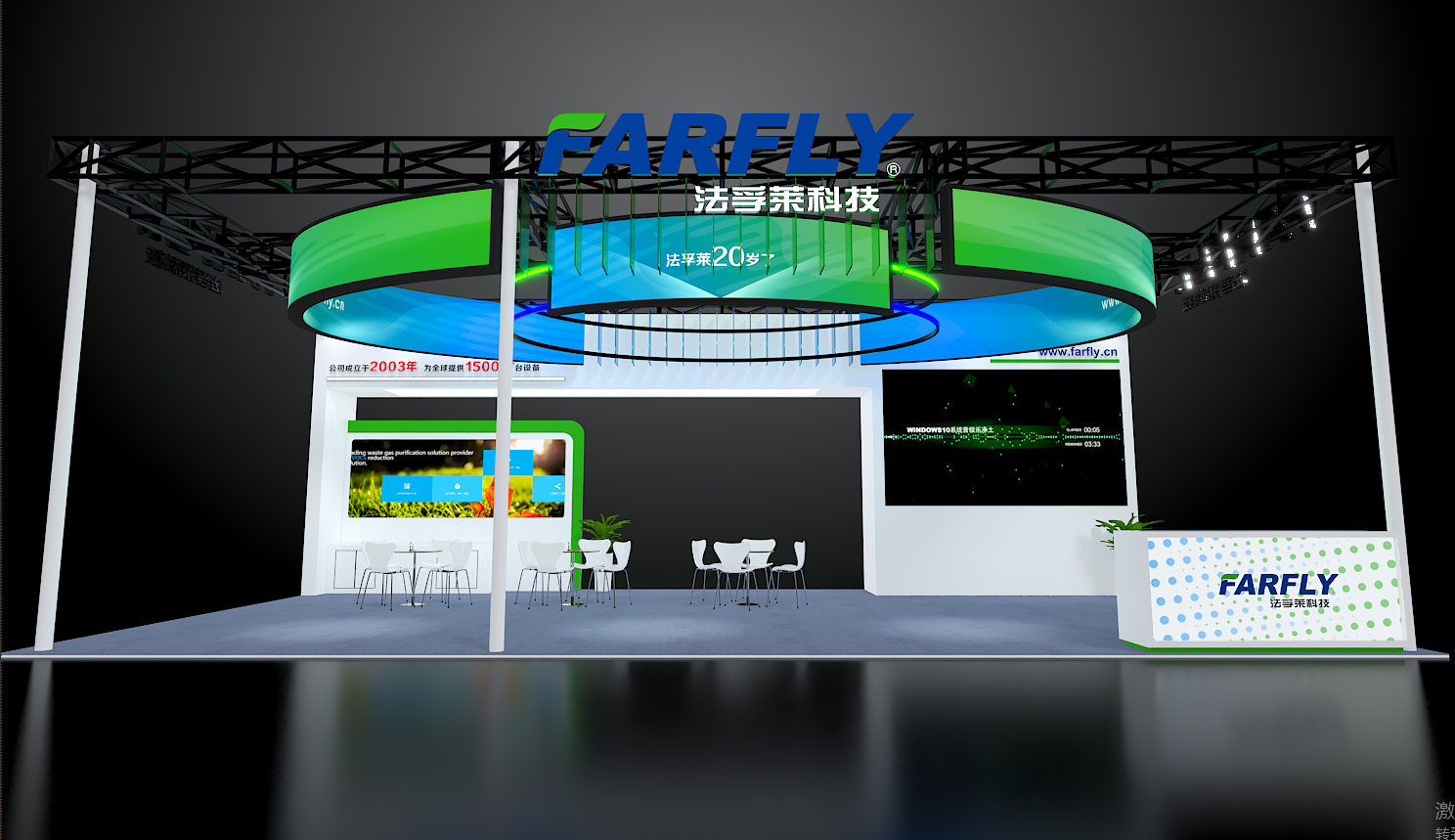

- Booth No. :52W03Shanghai National Convention and Exhibition Center

May 23-25, 2023contacts:Joana ShiEmail:sale@farfly.com1

Welcome to visit and exchange at the FARFLY booth.

FSP High flux sand mill

Characteristics

• High flux—technology imported from Germany:static centrifugal discharging devices, large discharge area with high output.

• Intelligent double-end mechanical seal: German mechanical seal technology, imported perfluorinated seal ring, can withstand a variety of solvents.

• Grinding area is made of special high wear-resistant alloy steel material ensuring long service life.

• Cooling efficiency: Adopting segmented double spiral channel is more conducive to heat and cold replacement. Cooling efficiency is twice that of ordinary types.

• Grinding efficiency: It is more than 30% higher than ordinary models. The combined disperser group of grinding turbine and dispersion grinding disc can be used to quickly improve the dispersion efficiency. The grinding medium can choose ultra-fine grinding media, which is more efficient.

FDS High efficiency super fineness sand mill

Application area

Digital printing ink, solvent ink, water-based ink, automobile paint, industrial coating, pigments, color paste, and nanometer materials.

• New design of pin-type grinding components,high grinding efficiency high output, and low energy consumption.

• With smaller length/diameter ratio and higher energy density.

• Using high flux static centrifugal separation sieve, large discharging area, grinding medium no contact with the sieve, no

abrasion, with longer service life.

• Grinding Barrel and grinding rotor adopt forced cooling system, with lower discharging temperature and no influence on sensitive

materials.

• Using top high quality wear-resisting alloy steel, reduce pollution to products. Different materials are optional as per different

products, such as stainless steel, high polymer materials, ceramics, etc.

FSA High-shearing emulsifier

Principle

The dispersing emulsifier is forming high frequency, strong tangential velocity and angular velocity by high speed and steady rotation of the

rotors; under the action of the stator, a strong,reciprocating hydraulic shear, friction, centrifugal extrusion, and liquid flow collision are formed in the reasonable and narrow gap between the stator and the rotors. It is suitable for efficient dispersing and mixing of solid and liquid materials.

FS Emulsify mixing reactor

Suitable for pre-dispersing and pre-mixing SC and producing in water and micro emulsion, with high efficiency, good quality and fully closed

production system. System configuration can be customized.

Farfly was founded in 2003. The company is a professional manufacturer of chemical machinery and equipment. The main products of the company are mixing equipment, dispersing equipment, high shear emulsification equipment, wet grinding equipment, powder mixing equipment and various reaction kettle, etc.And according to customer requirements to complete the core components of our products in the field of production line overall design, integration, installation and debugging.In 2020, the whole product series has passed the CE certification in line with the EU market.Farfly has been a member of China Coatings Industry Association.

Certificate

Over the past 20 years, the products have been exported to more than 100 countries around the world, and the export volume has been ranking first in the industry for years. Up to now, we have served more than 4000 companies, including many Fortune 500 companies. In 2020, although affected by the epidemic, under the leadership of the general manager Justin and the joint efforts of the staff of Farfly, the sales volume successfully exceeded 100 million. This year, Farfly successfully won the EPC project of the new Lankwitzer Anhui factory, and completed the layout of paint equipment for rail transportation and auto parts. Successfully signed a contract with Xiangjiang Group’s wholly-owned subsidiary, Twin Towers Coatings, which means that Farfly has become the benchmark equipment in the anti-corrosive coatings industry. In the same year, successfully signed the technical upgrading project of Nippon Marine Paint Grinding Workshop; Suzhou Kefaman Printing and Dyeing Pulp Equipment Project, a wholly-owned subsidiary of Shanghai Argus. As well as the new lithium battery material Dalian Sinoma to obtain cooperation. At the beginning of the New Year in 2021, it obtained a large order of 50 million yuan from three trees. This great achievement means that the development of Farfly in the field of coatings is growing steadily. We will make persistent efforts, determined to walk in the forefront of the industry.

Cooperation

Over the past 20 years, Farfly has been adhering to the “solution provider, enterprise construction service” business philosophy, always adhering to the “customer-centered”. High quality products, professional technology, perfect after-sales service by customers at home and abroad. Our products are not only limited to domestic, but also exported overseas. Africa, Europe, America, Southeast Asia and the Middle East all have our footprints. In the future, more and more domestic and foreign enterprises will choose Farflys. Thanks to the trust and support of our customers for a long time, we will never forget our original intention, go forward courageously, and aspire to become the leader of equipment in the coating industry. Welcome new and old customers to come to our booth to visit and exchange.